"Good design is a renaissance attitude that combines technology, cognitive science, human need, and beauty to produce something that the world didn’t know it was missing." – Paola Antonelli

Hello, everyone! I am glad to inform you that the Circularity Information Platform (CIP) evaluation session is accomplished. Great job! In this update, I share evaluation results and discussions with you.

After reading this update, you will understand:

- What is the research overview?

- What is a reference architecture model?

- What is the prototype design of CIP?

- What are the evaluation results?

- What do we learn from this research?

1. What is the research overview?

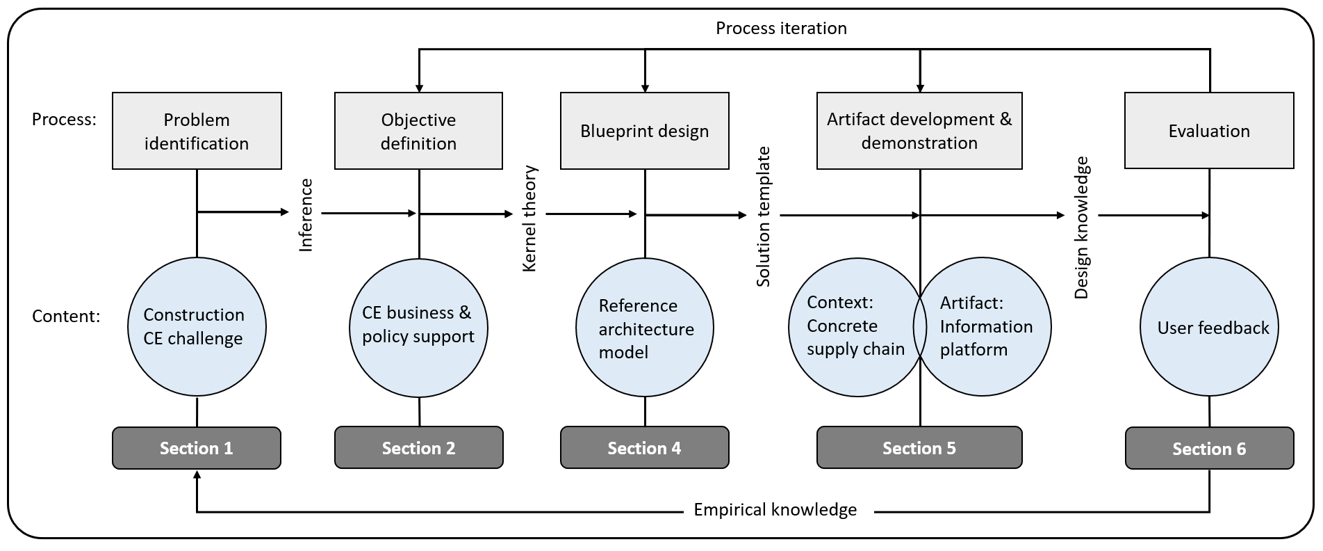

In this research, we adopt the design science research methodology. Design science is the design and investigation of prototypes in the context. We design, prototype, demonstrate, and evaluate the Reference Architecture models of CIP in the context of circular concrete supply chains. The research overview is shown in Figure 1.

Fig.1. Research Methodology

Fig.1. Research Methodology

2. What is a reference architecture model?

To guide the development of Information Systems, the concept of Enterprise Architecture was proposed by John Zachman in 1987. It is an enterprise engineering discipline that covers enterprise analysis, design, planning, and implementation activities. It focuses on the formal modelling of all the components that make up a complex enterprise system as well as on their inter-dependencies. Within the discipline of EA, a Reference Architecture (RA) model encompasses the knowledge about how to design robust Information system architecture by (1) capturing the essence of software architectures of specific application domains, (2) serving as standardization and evolution of the system through different development stages, and (3) reducing costs of maintenance and development of the system.

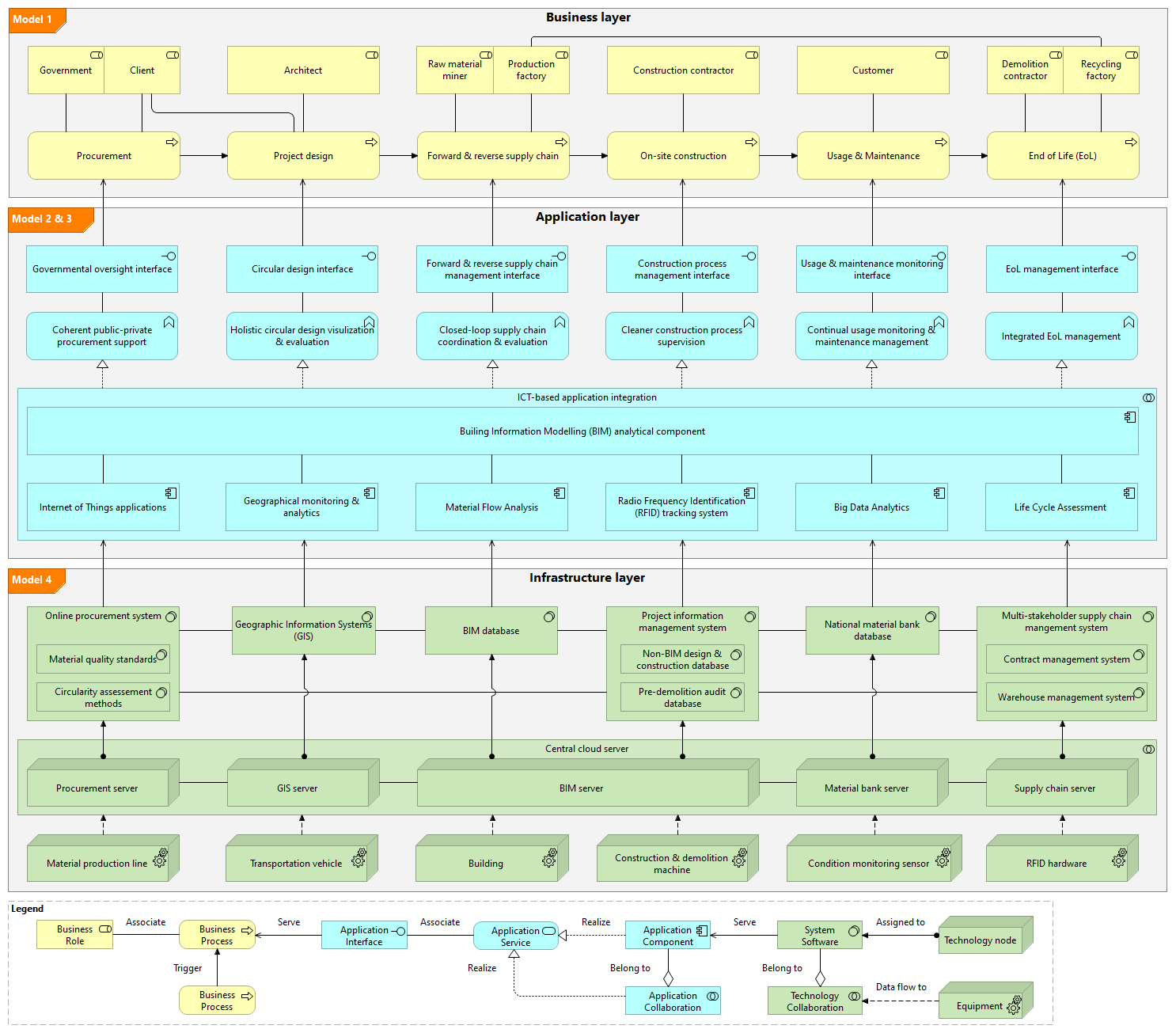

We review the literature and develop a design blueprint for CIP in the form of RA models. The high-level integration introduces a coherent overview of CIP at the business, application, and infrastructure layers. The master model can be viewed as a solution template for the design of CIP serving a multitude of purposes, including communication, evaluation, design, and redesign of the instrument (Figure 2).

Fig.2. Integrated View of RA models

Fig.2. Integrated View of RA models

The integrated RA model embeds the best Circular Economy (CE) industry practices and suggests optimal ICT integration. Beyond the graphical alignment, it underlines technological rules to flexibly intermediate the critical elements of construction CE at different layers through the lens of Information Systems. Notably, this is not an absolute definition of CIP but rather a structural abstraction for potential generalizations of CIP solutions.

We only present an integrated overview of the RA model in this update. Note that there are another four sub-models describing the details from different perspectives, respectively.

3. What is the prototype design of CIP?

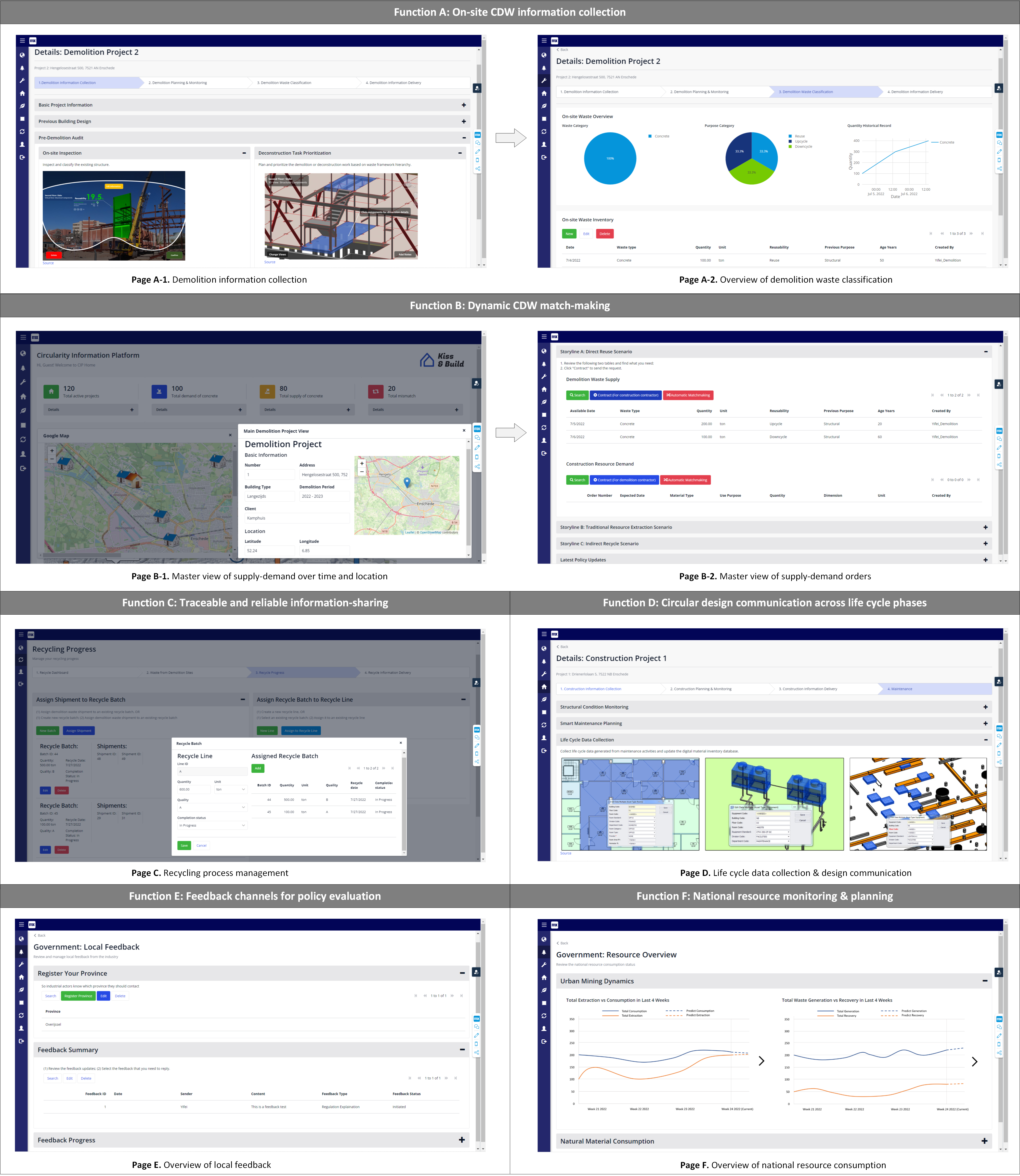

We select a circular concrete supply chain in the Twente region, the Netherlands, as the prototype context. First, we investigate a realistic problem context based on interviews with local actors, followed by a detailed analysis of the stakeholder requirement defining the functional scope. The defined functions are listed as follows:

- Function A: Support on-site Construction & Demolition Waste (CDW) information collection;

- Function B: Realize dynamic CDW matchmaking with efficient logistic planning;

- Function C: Ensure traceable & reliable information-sharing;

- Function D: Communicate circular construction design across life cycle phases;

- Function E: Create feedback channels for policy evaluation;

- Function F: Enable national resource monitoring & planning.

We develop a prototype of CIP for the circular concrete supply chain by Mendix. The design objectives are (1) streamlining the workflow of a circular concrete supply chain by providing different user interfaces with interviewed actors, and (2) mapping the potential roles of the identified functions on CIP. We demonstrate the artifact in Figure 3.

Fig.3. Screenshots of Six Functions of CIP Prototype

Fig.3. Screenshots of Six Functions of CIP Prototype

The prototype can be accessed via Mendix Cloud: here

4. What are the evaluation results?

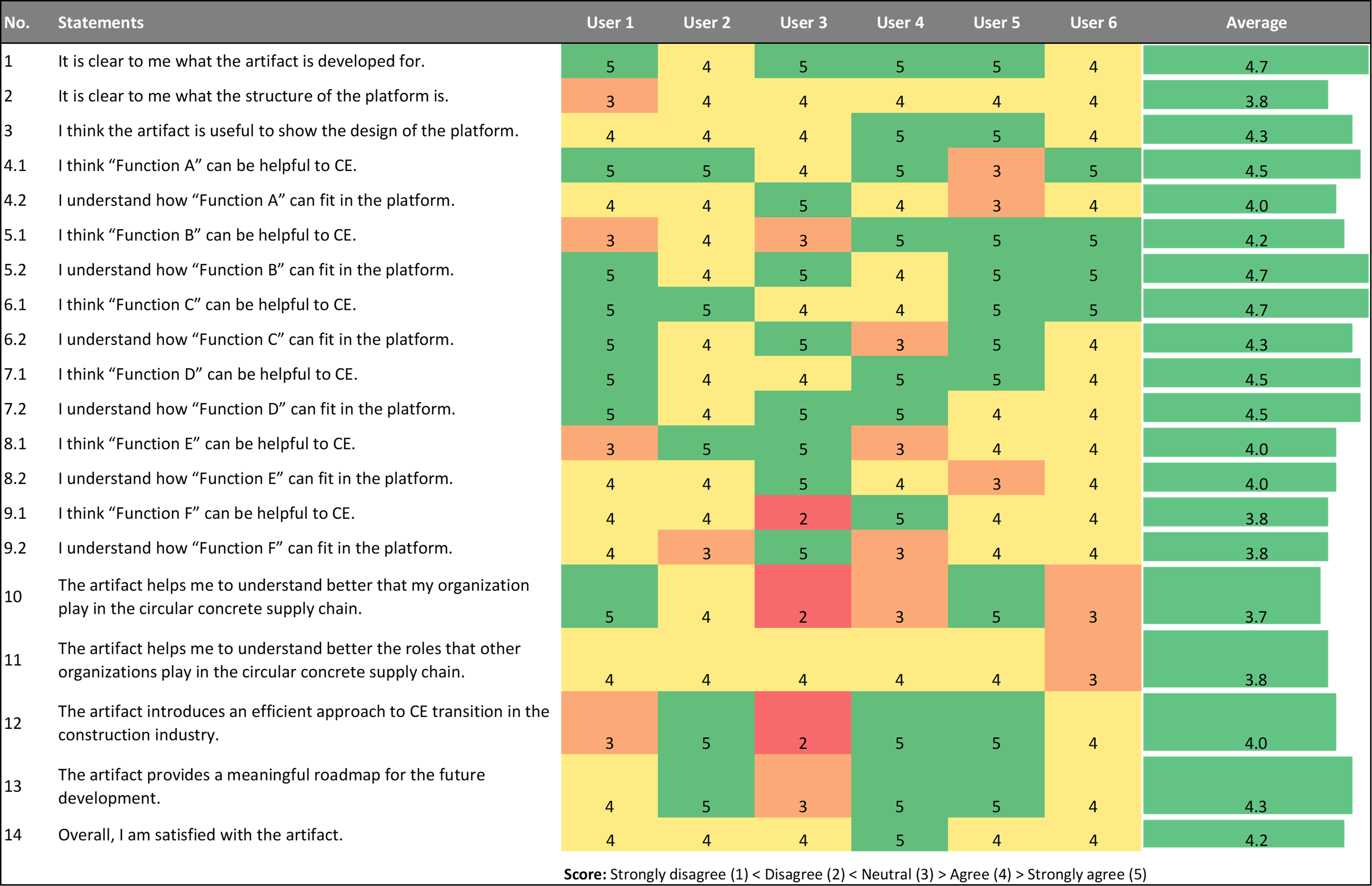

The interviewed actors are invited to evaluate the prototype regarding its simplicity, utility, and comprehensiveness in evaluation workshops. The evaluation form consists of statements rating the prototype's simplicity (statements 1-3), utility (statements 4-9), and comprehensiveness (statements 10-14).

- Simplicity: the prototype provides understandable descriptions of CIP's structure and functions;

- Utility: the prototype demonstrates useful and relevant functions;

- Comprehensiveness: the prototype includes mostly important elements and aspects of CIP.

First, the users agree that the prototype demonstrates a comprehensive roadmap of CE-oriented information systems in the construction industry. Although the prototype is yet ready for immediate deployment, it offers an informative ground where users can validate whether the design of CIP aligns with their expectations based on hands-on interactions. Users approve of the concept of closing the information gap between the forward and reverse supply chains by taking an inter-organizational approach. Therefore, the first three statements (simplicity) receive relatively high scores. In general, the prototype shows a clear system architecture of the platform.

Fig.4. Evaluation Results

Fig.4. Evaluation Results

Regarding the evaluation of the aforementioned six potential functions (utility), users show positive feedback. It is clear to them (1) how those functions could potentially fit in the platform and (2) why those functions are relevant to CE transition. However, the function of national resource consumption monitoring receives a relatively lower score because one evaluator underscores the difficulties of accurate data collection at a national level. Furthermore, the public actor indicates that it could be inappropriate to set the system boundary of CE at a national level when there are intensive cross-border collaborations regarding material transactions. This means that the platform configuration of public actors should be improved in the future.

On the one hand, users recognize the comprehensiveness of the prototype as they gain a clearer picture of the entire CE ecosystem after interacting with the prototype. It is interesting to observe that the prototype leads to a mindset change from a self-oriented individual perspective focusing on one company (in the interview) to a collaborative perspective aiming for mutual benefits for the network (in the workshop). On the other hand, users point out that the development of CIP requires long-term efforts from the industry because it entails an advanced level of digitalized and automatized collaborations. The industry still needs time to prepare accurate information and a sufficient workforce for it.

5. What do we learn from this research?

We summarize three learning points as follows:

1. Prioritize reduction and functional transformation as shortcuts to CE:

The public project manager states that the system needs to provide more opportunities for "reduce" instead of only focusing on "reuse" and "recycle". The prototype offers sufficient End-of-Life decision support. However, it is critical to promote reduction and avoid demolition by considering the possibilities of functional transformation and preserving the existing structure to the greatest extent. One suggestion is that the government user can be attached to a sub-role of clients who are responsible for the decision-making before demolition. More effort can be devoted to the pre-demolition audit to avoid extra consumption related to recovery treatments. Although other users argue that reduction may not be the best solution to meet the exponential construction demand in the market, it is reasonable to prioritize this concept in the future development of CIP.

2. Provide industry-wide quality criteria and storage space for a higher-level waste classification:

Users highly appreciate the information hierarchy system implemented in the production environment tracking the originality of material shipments. It can be an effective approach to Circular Economy in the future. However, users also indicate their concerns about its practical implementation. Since there are no unified quality assessment criteria for CDW, it is difficult to estimate the residual value of CDW. Besides, such a classification system requires more storage space for different types of waste. It is challenging to manage extra storage since the buffer space of warehouses is highly limited in practice. Therefore, providing unified quality assessment criteria for CDW and allowing extra storage space are vital to a higher-level waste classification in the future.

3. Resolve supply-demand mismatch by predictive and collaborative CDW matchmaking:

It is time-consuming to collect, treat, and verify secondary materials before transferring them to the new construction. A harmonized supply-demand relationship of secondary materials/items can be difficult to realize without any predictive supply or demand signals. The demands in the reverse supply chain should be scheduled in advance so that providers can customize treatment processes accordingly. For instance, the direct reuse of components can only happen when the demolition and construction contractors reach an agreement on the type and reusing purpose of components beforehand. Otherwise, the demolition contractor is not motivated to deconstruct components with higher costs. We argue that the concept of "supply chain" can be complemented by introducing a corresponding "demand chain" so that a holistic overview of supply-demand mismatch becomes explicit.

However, the unstable and limited supply of secondary materials is fatal to supply-demand matchmaking on a large scale. The receiver would not easily place the order if the provider cannot guarantee a constant supply of qualified materials. Adding to the challenge above, it leads to a dilemma where both sides wait for each other to take the first action. Therefore, predictive and collaborative supply-demand matchmaking is vital to CE creating more opportunities for customized CE exchanges. Instead of only considering quantity and quality, it is suggested to include more detailed specifications of materials/components, such as geometrical dimensions, in the platform to improve the efficiency of matchmaking.

Summary

We accomplished CIP's prototype development and evaluation. Now, we are preparing the submission to a suitable academic journal. More information about the publication will be provided soon.

Next step

The concept of CIP is complex. To fit it into a 4-year-programme, we need to smartly address the research boundary. Now that the entire roadmap is revealed, it is time to have a focus. Therefore, we will focus on the function of Waste-to-Resource Matchmaking in the next research stage. Particularly, we aim to understand what are the steps that a computer needs to go through to realize this function, if many users offer information about "waste" and require information about "resources" on the platform. We will provide a research plan with you at the end of 2022.

Thank you again for your generous support!